In the new energy vehicle industry, the performance and safety of on-board chargers (OBC) and DC-DC converters are crucial for automobiles. OBC is responsible for converting AC power into DC power suitable for battery charging, while DC-DC converters convert the high-voltage electricity in batteries into low-voltage energy to power the vehicle’s electronic systems.

Thus, it is necessary to conduct an EV DC DC converter and OBC test to ensure their stability, efficiency, and safety. It helps to verify the reliability of the design and ensure that the product can function properly under various working conditions.

This article will explore advanced DC-DC and OBC test solutions. Read on to learn more!

Table of Contents

ToggleOBC and DC-DC Converters: Functions in EV Systems

OBC in cars are responsible for converting alternating current from external charging sources into direct current to charge the EV batteries. They manage the entire charging process for safe and efficient energy transfer. They also monitor battery conditions, temperature, and voltage levels. The OBC system is a critical interface between the electricity grid and the vehicle’s energy storage system.

DC-DC converters play a crucial role in managing power distribution across different voltage systems within the electric vehicle. They transform high-voltage battery power into lower-voltage power needed for auxiliary systems like lighting and in-car infotainment systems. These converters ensure stable and reliable DC DC power supply to various vehicle subsystems.

Challenges of DC-DC and OBC Testing

Given the importance of DC-DC converters and OBCs, there are currently testing methods available to verify their performance. However, traditional DC-DC converter and OBC tests present a complex array of challenges, including:

1. System Integration and Compatibility

Firstly, ensuring compatibility and stability between various equipment is a big challenge. DC-DC converter and OBC test involve multiple testing equipment, including power supply, load, oscilloscope, wave order, etc.

There may be technical barriers between different devices and instruments, leading to complex integration processes that involve the collaborative work of hardware and software.

2. Dynamic Conditions and Load Fluctuations

In order to comprehensively evaluate the performance of OBC and DC-DC converters, multi-condition testing is required. This includes different load conditions, environmental changes, and dynamic operations to verify the performance of the product in practical applications.

However, the challenge lies in simulating transient load conditions and recording dynamic data. This increases the difficulty and labor cost of OBC car testing and reduces testing efficiency.

3. Test Automation and Flexibility

In order to achieve efficient DC-DC converters and OBC tests, a flexible and automated testing platform is also required. Automated testing should not only cover various testing scenarios but also be able to quickly adapt to new testing requirements and technological changes.

But the testing challenge lies in the need for testers to manually write and debug each test case, which is not only time-consuming and labor-intensive, but also has a high technical threshold. In addition, the capture and recording of test results are not intelligent enough and often require manual intervention.

4. Industry Standards and Regulatory Requirements

Compliance with evolving international standards and regulatory requirements adds complexity to the DC-DC converters and OBC test. Different countries and regions may have different industry standards, and industry standards may be constantly updated with the development of technology.

Thus, it necessitates comprehensive and adaptable solutions. The global EV market demands navigation through region-specific safety, performance, and environmental regulations.

5. Data Recording and Analysis

Capturing, processing, and analyzing extensive OBC test data requires high-precision and automated testing equipment to ensure the accuracy of data and derive meaningful performance insights. In addition, fixed report styles often fail to meet the requirements for recording and analyzing test data for different projects, limiting the flexibility and usability of test reports.

ActionPower Offers an Advanced DC-DC and OBC Test Solution

To address the challenges of EV DC DC converter and OBC testing, ActionPower has developed an advanced electric vehicle OBC/DC-DC testing solution aimed at covering OBC/DC-DC testing of various powers and improving testing efficiency. It stands out because of:

1. Highly Integrated System

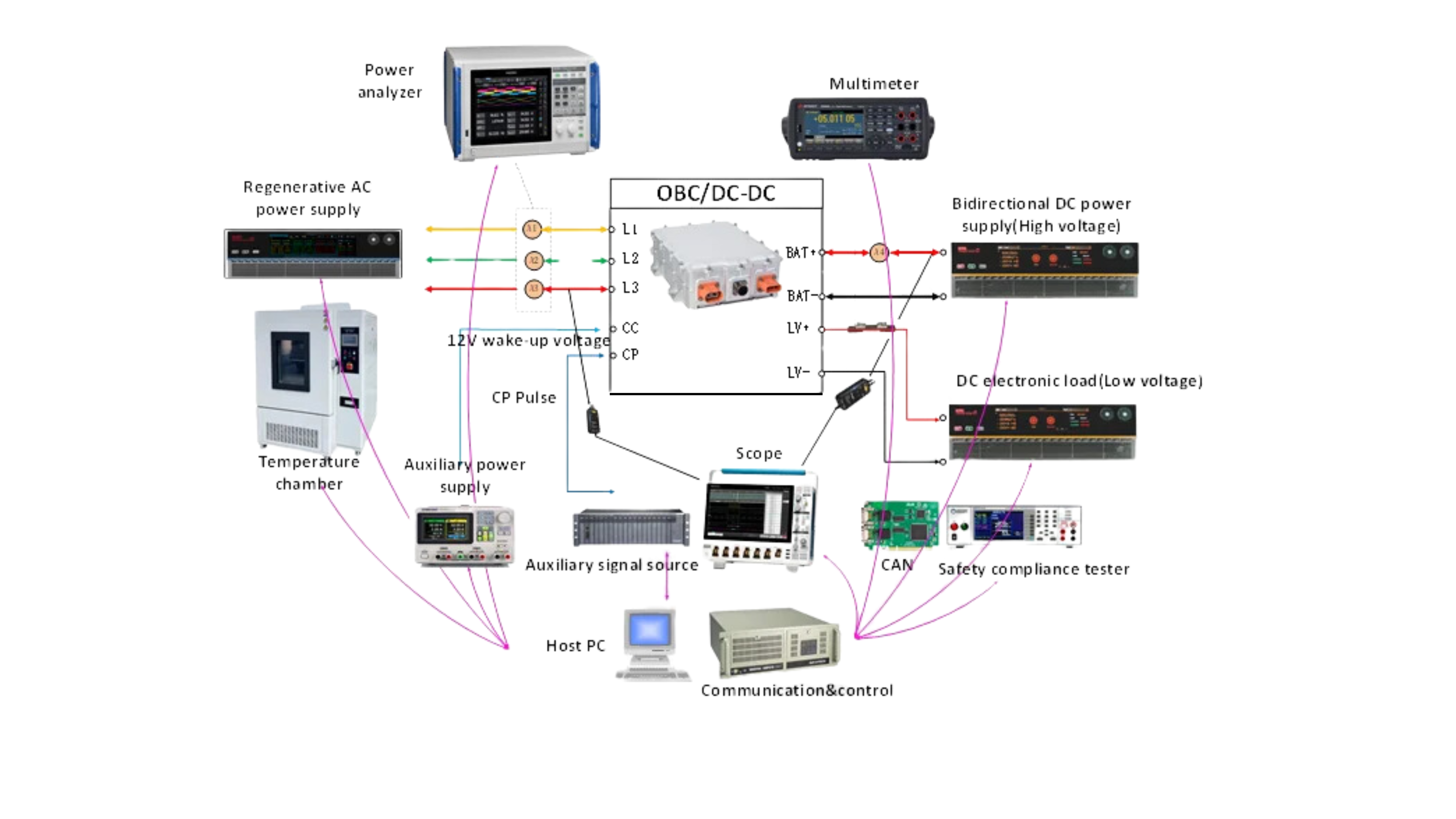

Our solution integrates multiple devices, such as power supply, load, oscilloscope, etc, into a multi-functional platform. This integration saves significant equipment space, simplifies wiring, and achieves significant cost reduction, making task processing more efficient and convenient.

Moreover, the modular EV OBC test system design allows customers to add or reduce hardware as needed. It facilitates maintenance and reduces maintenance costs.

2. Full Power Coverage, Meeting Multiple Standards

We ensure comprehensive OBC/DC-DC power coverage from 0 to 40kW. Moreover, this testing solution meets numerous international standards, including:

- GB/T 18487.4-202× Electric Vehicle Conduction Charging and Discharging System Part 4: Discharging requirements for electric vehicle

- GB/T 18487.1-2023 Electric Vehicle Conductive Charging System Part 1: General Requirements

- GB/T 36457.2-2017 Interoperability Test Specifications of Electric Vehicle Conductive Charging

- GB/T 40432-2021 Conductive On-Board Charger for Electric Vehicles

- GB/T 24347-2021 DC/DC Converter for Electric Vehicles

- QC/T 895-2011 On-Board Conductive Charger for Electric Vehicles

Additionally, our system can be expanded to support LV123, VW80300, VW80303, and IS021498-2 European and American standards.

3. Wide Compatibility and Safety

We break down system barriers by integrating instruments from mainstream manufacturers. Our OBC test solution offers open user-defined driver templates and enables seamless interchange of ATE test equipment.

The EV OBC system adopts modular authorization with the collaborative development of different testing personnel to ensure process confidentiality and system security.

4. Comprehensive Working Condition Simulation without Hardware

Our EV DC DC converter and OBC test solution enable sophisticated simulation of diverse operational scenarios. It supports fast verification testing solutions without hardware, which can expose system issues early, save research costs, and improve development efficiency. It covers 14 comprehensive test categories, including:

- Current ripple

- V2V fault simulation

- V2L fault simulation

- DC-DC active/passive discharge

- Insulation fault detection and more

5. Whole Process Automation

The system’s automated testing procedures dramatically reduce human intervention and potential errors. They enhance overall testing efficiency. Our solution supports:

- Automatic analysis of CAN messages and oscilloscope waveforms

- Automatic control of pilot signals CC, CP, insulation, and temperature

- Automatically triggered wave recording equipment

- Accurately anchor the test interval and capture the required waveform screenshot.

6. Easy Construction of Testing Plan

Intuitive interfaces allow quick and straightforward DC-DC/OBC test plan development. They reduce setup time and complexity. Built-in industry-standard test programs allow:

- One-click program retrieval

- Test plan construction without coding knowledge

- Quick test plan creation through use case combinations

7. One-Click Generation of Test Report

Our OBC automotive test solution boasts comprehensive reporting capabilities. These enable rapid result analysis and documentation with minimal manual intervention. The key reporting capabilities include:

- Automatic result analysis

- Detailed test report generation with a single click

- Customizable report styles

Conclusion

Overall, the DC-DC converter and OBC testing is a critical aspect of electric vehicle development. It directly impacts vehicle performance, safety, and reliability. At ActionPower, our comprehensive testing solution addresses the key challenges. For an efficient R&D process, visit our website to explore our full range of testing solutions!