The continuous advancement of technology has enabled the integration of the Internet of Things (IoT) into our daily lives. From smart homes to industrial automation, the connection between devices and the Internet has become smoother than ever before.

This growth trend places higher demands on battery technology, as most IoT devices rely on batteries to provide reliable energy. It is necessary to test battery performance to meet the power supply needs of the equipment.

The traditional method of using real batteries for testing is often time-consuming and labor-intensive, requiring multiple charge and discharge cycles to evaluate batteries’ performance. In contrast, modern battery simulators provide a fast and accurate solution, allowing quick battery state changes to shorten the testing cycle.

Let’s explore further how battery simulators boost your battery performance!

What is a Battery Simulator?

Battery simulators are advanced electronic devices made to simulate the functions of a real battery.

Unlike physical batteries, a battery pack simulator acts like a flexible, programmable battery that provides the required voltage, power, and current. It allows you to test battery chargers by replicating how real batteries react during the charging and discharging process.

Instead of spending hours waiting to charge a real battery from empty to full, a battery simulator instantly adjusts its output voltage. For instance, it goes from 0V to 4.2V in seconds, acting as a valuable tool for assessing battery chargers in a controlled environment to save both time and resources.

What are the Functions of Battery Simulators?

The global battery simulator market is expected to reach up to $766.4 million by 2030. [1] This surge indicates that battery simulators play a vital role in testing and optimizing battery performance today.

Here’s a list of the core functions of battery simulators:

1. Simulate Various Working States of Batteries

As mentioned earlier, battery simulators can act as batteries and simulate their states under different working conditions, including the charging and discharging process, the response under various load conditions, etc.

They can provide precise voltage and current outputs to test the reliability and performance of electronic devices. They also help users check how well a battery management system (BMS) system performs and adapts to changing conditions.

By using simulators, you can easily fine-tune your battery system and reduce the inconsistencies you might face with real battery packs.

2. Battery Safety Test

In IoT applications, devices typically work under sensitive conditions, making safety a top priority. Fortunately, battery simulators perform various safety tests to ensure batteries work optimally within specified safety ranges.

For example, a battery simulator power supply can simulate the working state of a battery under extreme conditions, such as overcharging and overvoltage. It can also simulate extreme conditions such as high temperatures and short circuits to test the reaction and endurance of batteries, providing reference data for battery design and improvement.

3. Battery Life Test

Additionally, battery simulators allow the conduct of long-term charge and discharge cycle tests to evaluate the stability and lifespan of the battery.

These life tests via battery simulation help predict battery decline, capacity loss, and how long the battery will remain durable, providing the reference for research and quality control.

Application of Battery Simulator in IoT Battery Testing

Battery cell simulators play a vital role in IoT battery testing under various conditions to evaluate battery performance and systems. It includes the following:

1. Smart Home Devices

Smart home devices, such as safety cameras, smart door locks, thermostats, refrigerators, TVs, and lights, rely on batteries to operate.

Battery simulators step in to test these devices’ battery performance under different conditions to test their reliability over time. For instance, simulators can replicate the power of thermostats to help manufacturers optimize their battery life and make them more efficient.

2. Smart Vehicles

Smart electric vehicles rely heavily on battery management systems (BMS) as they directly affect the vehicle’s operational efficiency and safety.

The battery pack simulator can simulate various battery conditions and extreme situations to test the response and management capabilities of BMS, such as overcharging, overvoltage, and extreme temperature.

It can also evaluate the energy consumption of in-vehicle systems in different driving modes, helping to adjust driving strategies or vehicle design.

3. Smart Industrial Equipment

In industrial IoT applications, the demand for automation and smart devices is increasing, and reliability is the top priority.

These applications include sensors, machinery, or monitoring systems that require steady operation. Battery cell simulators test the battery performance of this equipment in a high-demand environment.

This ensures that industrial equipment will perform optimally under all circumstances, such as extreme temperatures, hours of continuous operation, or different load conditions.

In summary, battery simulators have demonstrated their irreplaceable importance in various fields of the Internet of Things, helping to improve the reliability of IoT devices in terms of battery performance and safety management.

Where to Buy Battery Simulators?

For top-notch battery simulation, ActionPower provides an ABS battery simulator power supply that offers accuracy and fast performance to meet various testing needs. It features high accuracy, high dynamics, high real-time performance, and comprehensive battery characteristic simulation.

It can simulate the output characteristics and charge or discharge characteristics of various battery packs, such as lithium manganate, lithium cobaltate, lithium iron phosphate, etc. It can also set parameters such as series/parallel quantity, temperature, SOC, etc., to simulate the output characteristics of the entire battery pack.

Moreover, ActionPower’s PRD Bidirectional DC Power Supply is a programmable unit with source and load functions. It has the characteristics of high power density, high precision, and high dynamics.

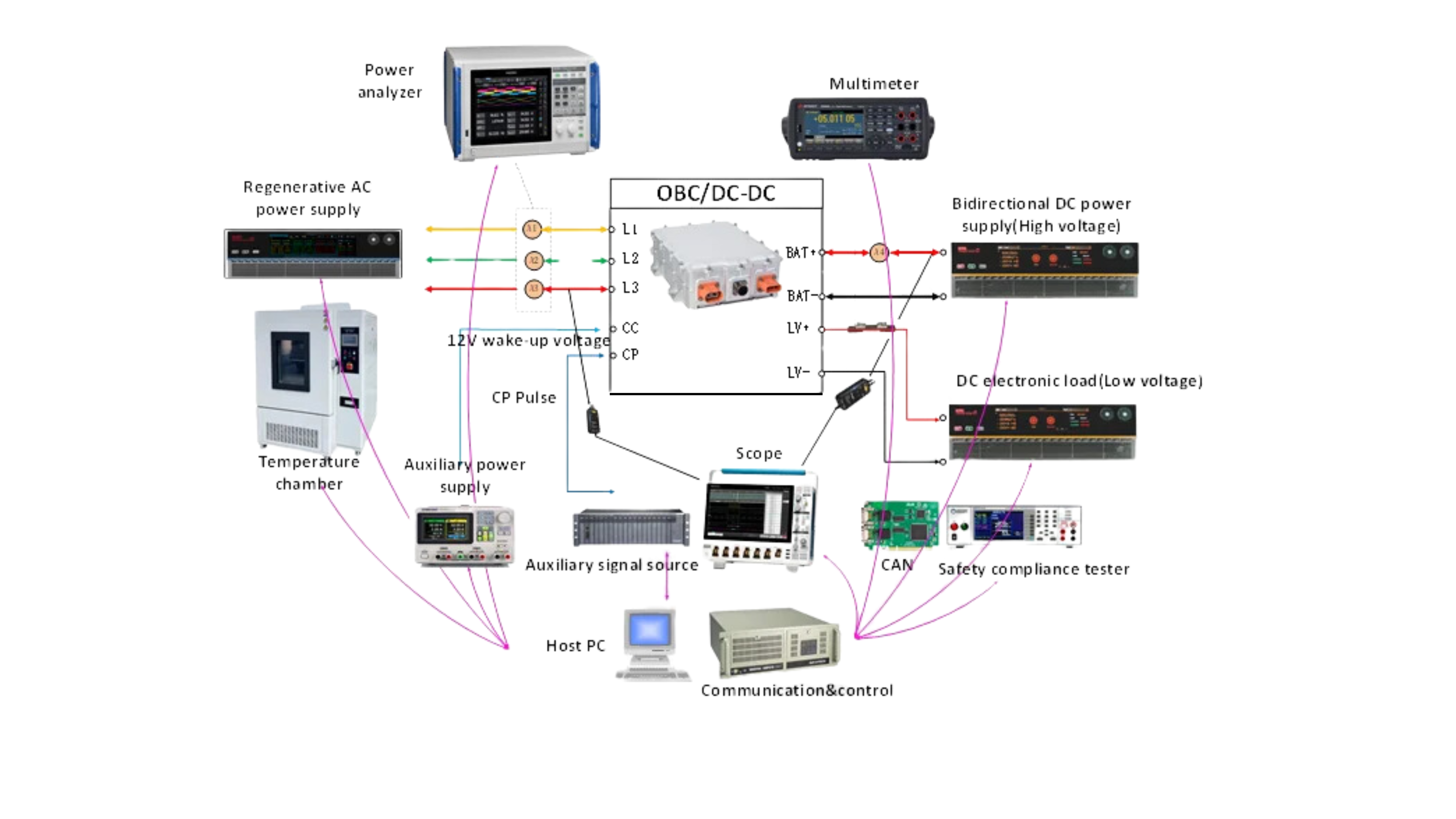

It employs an automatic two-quadrant operation and the ability to absorb energy from the unit under test (UUT) and feedback to the grid. This battery simulator test equipment works best for simulating energy storage batteries, capacitors, and electric vehicle on-board chargers.

Wrapping Up

When it comes to the rapid advancement of IoT technology, reliable battery testing methods are important. Battery simulator test equipment is useful for performing battery safety tests, life tests, and simulating different battery states. This helps users gauge and optimize battery performance for multiple IoT applications without running into issues.

For those seeking top-quality simulation, tools like the ABS High Power Battery Simulator and PRD Bidirectional DC Power Supply from ActionPower stand out as top picks for many. Contact us for specific information!

References

[1] Battery Simulator Market Trends and Analysis: Navigating the Landscape for 2032. Available at: https://www.linkedin.com/pulse/battery-simulator-market-trends-analysis-navigating-zeubf/ (Accessed: 28 August 2024)