The boom in the EV market not only drives the advancement of electric vehicle technology but also promotes the development of related infrastructure, especially high-power EV chargers. High-power EV chargers can provide a fast and efficient power supply, greatly reducing the charging time of electric vehicles.

In order to ensure their performance and stability, EV charger testing has become an essential key step. However, the increasing capacity of charging stations makes traditional EV charger testers less effective in terms of testing efficiency, cost, and functions. Therefore, the shift towards advanced EV charger testing solutions becomes greatly urgent.

Read on to find out the EV charger testing challenges and advanced testing solutions!

Table of Contents

ToggleImportance of High-Power EV Charger Testing

Why do we need to test high-power charging stations? Testing this widely used charging facility is crucial for ensuring charging safety, evaluating and optimizing the performance of charging stations, and promoting innovation in charging technology.

1. Ensure Charging Safety

This is the most fundamental and important reason. High-power EV chargers generate high current and high voltage during operation. If there are any defects or faults in design, it may lead to serious safety accidents such as overheating, short circuits, and even fires.

This will not only endanger the costly equipment but also people in the surrounding area. For this reason, high-power EVSE testing can be used to identify potential hazards in a timely manner, ensuring the safety of personnel and equipment.

2. Evaluate and Optimize the Performance of Charging Stations

EV charger testing can help manufacturers evaluate and optimize the performance of charging stations. By simulating different charging scenarios and load conditions, the efficiency, response time, remote monitoring function, and charging speed of the EV charger can be measured.

These data are crucial for the continuous improvement of products, helping to provide faster and more reliable charging experiences and enhance market competitiveness.

3. Promote Innovation in Charging Technology

Besides ensuring safety and smooth operation, testing electric vehicles is also very important for innovation. A charger that is working great now may not remain compatible a few years later.

Through testing, the effectiveness of new technologies and improvement measures can be verified, promoting the development and application of innovative technologies.

What are the Challenges in High-Power EV Charger Testing?

As we’ve discussed, a high-power EV charger tester is very important. However, it’s not as easy as it sounds because of the following challenges:

1. Restrictions on Power Infrastructure

For most current charging stations and module manufacturers, high-power EV charger testing may consume a large amount of electricity, which can cause additional load pressure on existing power infrastructure.

Due to limitations in the capacity of power transformers, distribution switches, and the diameter of distribution lines, the current aging infrastructure is no longer able to meet the production and testing needs of high-power EV chargers and modules.

2. Conflict Between Testing Costs and Environmental Protection

During the production and testing process of high-power charging stations, electricity consumption will significantly increase. It not only directly leads to an increase in production costs but also goes against the sustainable development goals. Therefore, how to reduce testing costs while ensuring testing quality has become an urgent problem to be solved.

3. Insufficient Function of Testing Equipment

Many early-deployed AC power sources, loads, and other equipment used for EV charger testing can only be tested for specific parameters, lacking comprehensiveness and flexibility. In addition, the difficulty in integrating different devices also leads to more complex testing and greatly reduced efficiency.

4. Low Automation Level in Testing

Traditional EV charger testing methods rely on manual operation, which is not only inefficient but also easy to cause errors, especially in long-term repetitive testing.

The manual recording and analysis of data are time-consuming and laborious, and it is difficult to monitor parameters such as battery temperature, voltage, and current in real time, making it impossible to accurately control the charging process.

What is the Best High-Power EV Charger Testing Solution?

Given the numerous challenges faced in high-power EV charger testing, ActionPower has proposed an innovative testing solution. Our solution adopts advanced control technology and algorithms, which can control the AC input current harmonics of the power supply and the current harmonics feeding back to the grid below 3%. It can cover testing scenarios of charging stations and modules of different power levels.

This not only reduces the electricity costs during R&D and production processes but also eliminates the need for upgrading existing distribution lines.

1. Solution for High-Power EV Charger Testing

Our PRO bidirectional programmable power supply is designed specifically for high-power EV charger testing.

The PRO bidirectional programmable AC power supply can simulate high-capacity and high-load power grids, supporting a maximum capacity of 675kVA per unit. The maximum power of the PRO bidirectional programmable DC power supply is 750kW per unit, which has the characteristics of high precision, high dynamics, and high real-time performance. It can comprehensively simulate battery characteristics. Both can be expanded in parallel.

In addition, both have low current distortion rates, saving over 90% of electricity during testing to reduce costs and meet the future research and production needs of high-power charging stations.

2. Solution for High-Power Charging Module Testing

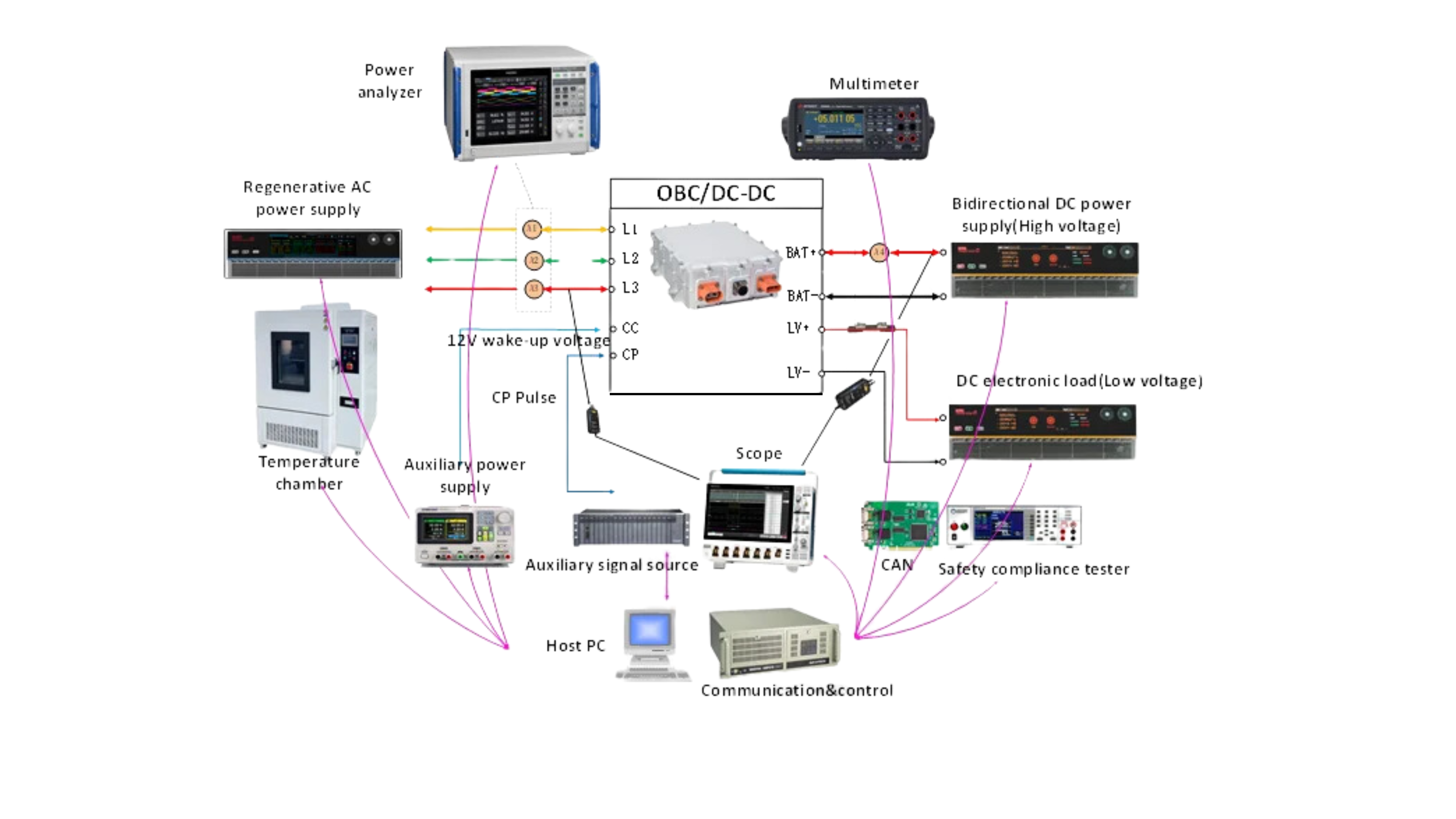

Our PRE20 Programmable Regenerative AC Power Supply and PRD Bidirectional DC Power Supply testing system is designed specifically for testing high-power charging modules.

PRE20 has a maximum capacity of 22kVA and can be expanded to 220kVA in parallel. It simulates the waveform of the power grid accurately, with an input power factor higher than 0.99 and a current distortion less than 3%.

PRD has the characteristics of high precision and high dynamics. Its single-unit power is 30kW, and up to 100 units can be connected in parallel to form a 3000kW source-load system. When used as a load, its current distortion is less than 3%, saving over 90% of electricity and reducing distribution capacity requirements.

During the entire process, the testing equipment can be intelligently controlled by our Action2020 power supply test software. It can monitor and collect real-time data such as battery temperature, voltage, and current to improve charging technology. It also helps greatly reduce testing efficiency and cost.

3. Case Analysis

For example, in the R&D and production testing of supercharging stations for a leading electric vehicle company, our 1.44MW supercharging station testing system helped save about 90% of electricity consumption, achieving green and low-carbon production.

Conclusion

How to test a charger effectively? If you’re an electric charging station manufacturer, the most important thing for handling the growing demand for high-power EVSE testing is to choose the correct and efficient testing solution.

So don’t waste money and time on traditional methods, and get ActionPower’s testing solutions today. We’ll help you maximize the efficiency of your EV charger testing process and also build your reputation as an environmentally friendly company!